EV, Hybrid & High-Voltage System Diagnostics

- chepqofficial

- Dec 19, 2025

- 3 min read

Updated: Dec 30, 2025

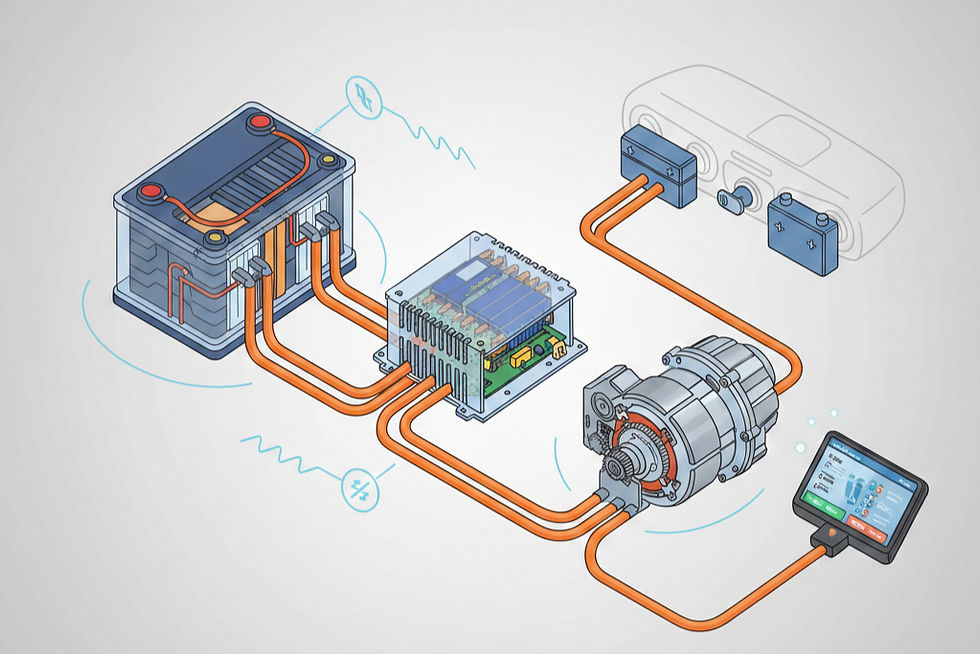

Electrified powertrains introduce fundamentally different diagnostic challenges compared to conventional vehicles. High-voltage energy storage, power electronics, thermal control, and safety isolation systems operate as an integrated architecture rather than independent components.

Diagnostics in EV and hybrid systems therefore focus on system coordination, electrical integrity, and safety-state logic.

High-Voltage Architecture Overview

Electric and hybrid vehicles separate low-voltage control systems from high-voltage propulsion systems. Traction batteries, inverters, electric motors, and on-board chargers operate within controlled high-voltage domains.

Isolation barriers, contactors, and monitoring circuits regulate energy flow. High-voltage diagnostics evaluate whether energy pathways remain controlled under all operating conditions.

Traction Battery as an Energy System

The High Voltage Battery functions as an energy storage and management system rather than a passive reservoir. Cell groups, modules, and pack-level supervision coordinate to deliver stable power.

Battery behavior depends on state of charge, temperature, internal resistance, and load dynamics. Diagnostic interpretation considers energy flow rather than static capacity values.

Battery Management System Coordination

The Battery Management System (BMS) supervises voltage, current, temperature, and balancing operations. BMS logic determines charging limits, power availability, and fault responses.

Inconsistencies between measured values and calculated state variables alter vehicle performance without immediate fault indication. BMS diagnostics evaluate logic coherence alongside raw measurements.

High-Voltage Isolation and Safety Monitoring

High-voltage systems incorporate continuous isolation monitoring. Leakage paths between high-voltage conductors and vehicle chassis trigger safety responses.

Isolation degradation may appear only under specific conditions such as humidity, vibration, or temperature change. Safety logic may limit propulsion before fault thresholds are exceeded.

Isolation diagnostics explain power limitation without component failure.

Inverter and Power Electronics Behavior

The Inverter Module converts DC battery energy into controlled AC motor drive. Switching behavior introduces thermal and electrical stress.

Abnormal switching patterns affect torque smoothness, efficiency, and noise. Diagnostics focus on waveform stability, thermal response, and coordination with motor feedback.

Power electronics diagnostics bridge electrical and mechanical domains.

Electric Drive Motor Integration

The Electric Drive Motor responds to precise inverter control. Torque delivery depends on current regulation, rotor position feedback, and thermal limits.

Motor performance degradation may originate from inverter control, sensor alignment, or thermal constraint rather than mechanical wear.

Diagnostics correlate electrical input with mechanical output.

Charging System Coordination

On-board chargers, external charging stations, and vehicle control systems negotiate power transfer dynamically. Charging behavior depends on communication protocols, thermal limits, and battery condition.

Charging interruptions or reduced rates often reflect protective logic rather than infrastructure faults. Diagnostics examine negotiation state and control logic alignment.

This links charging diagnostics to Onboard Charger (OBC) behavior and vehicle control strategy.

DC-DC Conversion and Low-Voltage Support

The DC-DC Converter supplies low-voltage systems from the high-voltage battery. Stability of this conversion affects ECUs, networks, and sensors.

Irregular low-voltage behavior in EVs frequently originates from DC-DC instability rather than auxiliary battery failure.

Power-domain interaction diagnostics connect high-voltage systems to conventional electrical analysis.

Thermal Management Integration

Thermal control governs battery longevity, power availability, and charging performance. Pumps, valves, heat exchangers, and control logic operate continuously.

Thermal imbalance alters electrical characteristics without mechanical fault. Diagnostics consider temperature gradients alongside electrical measurements.

Thermal diagnostics integrate with Thermal Management System behavior.

Regenerative Braking Interaction

Regenerative Braking couples propulsion control with energy recovery. Braking force distribution depends on battery acceptance, motor capability, and safety constraints.

Regeneration limitation affects deceleration feel without braking system faults. Diagnostics evaluate coordination between braking, power electronics, and energy storage.

Safety States and Functional Limitation

High-voltage systems prioritize safety. Detected anomalies trigger staged responses including power reduction, isolation, or shutdown.

These states persist until validation conditions are met. Functional limitation often appears without explicit fault indicators.

Understanding safety-state transitions explains reduced performance conditions.

Network Dependency in Electrified Systems

EV and hybrid systems rely heavily on synchronized communication. BMS, inverter, charger, and thermal controllers exchange time-critical data.

Network instability alters power availability and safety logic. This ties EV diagnostics to Vehicle Network Architecture Diagnostics.

Data Integrity and Memory Effects

High-voltage systems store operating history, fault counters, and adaptive parameters. Memory inconsistencies affect charging behavior and power limits.

Persistent limitations may reflect stored safety states rather than active faults.

Diagnostics include evaluation of retained system state.

Environmental and Usage Influence

Temperature extremes, fast charging patterns, and duty cycles accelerate system adaptation. Environmental influence explains seasonal or usage-dependent behavior changes.

Longitudinal analysis clarifies degradation trends.

High-Voltage Diagnostics as System Validation

EV and hybrid diagnostics validate coordinated operation across electrical, thermal, and logical layers. Component-level testing alone fails to explain system behavior.

System-level interpretation ensures accurate fault attribution.

Integration Within the Diagnostic Framework

This pillar integrates with:

High-voltage diagnostics expand the diagnostic framework into electrified propulsion.