Sensor Signal Integrity & Data Validation Diagnostics

- chepqofficial

- Dec 19, 2025

- 3 min read

Updated: Dec 30, 2025

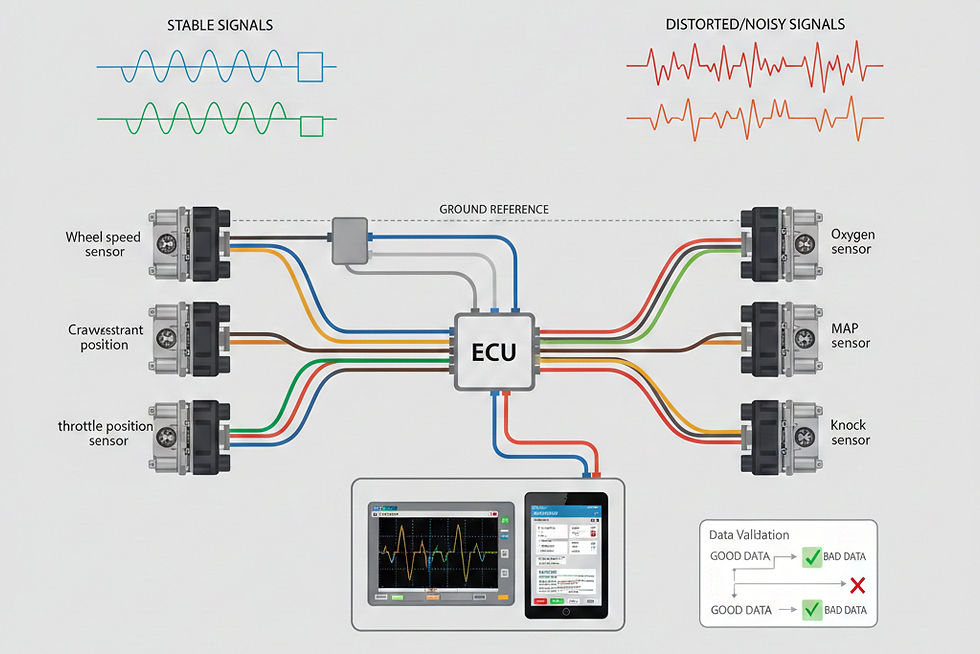

Modern vehicles rely on sensor data as the primary input for all control decisions. Engine management, braking systems, chassis control, driver assistance, and energy management systems interpret physical conditions exclusively through sensor signals. The accuracy of these signals determines whether control logic reflects reality or responds to distorted information.

Sensor signal integrity diagnostics therefore focus on validating data quality rather than confirming component presence.

Sensors as Data Translation Interfaces

Sensors convert physical phenomena—pressure, temperature, position, speed, acceleration, chemical composition—into electrical signals. These signals are interpreted by ECUs as numerical values, forming the basis for real-time control and long-term adaptation.

Components such as the Throttle Position Sensor (TPS), Manifold Absolute Pressure (MAP) Sensor, Mass Air Flow Sensor (MAF), and Crankshaft Position Sensor serve as reference points for control algorithms. Any deviation in signal accuracy propagates through the system, influencing fuel delivery, ignition timing, torque management, and emissions control.

Signal Integrity Beyond Fault Codes

A sensor may operate within nominal voltage ranges while producing distorted or unstable data. Diagnostic trouble codes often trigger only when signals exceed predefined thresholds, leaving marginal or drifting signals undetected.

Signal integrity diagnostics focus on waveform behavior, timing consistency, amplitude stability, and correlation between related signals. A sensor may pass static checks while failing dynamically under load, temperature variation, or vibration.

Reference Voltage and Ground Dependency

Most sensors rely on shared reference voltages and ground circuits. Variations in reference stability alter signal scaling without changing the physical condition being measured.

A degraded ground path or reference voltage fluctuation shifts sensor output across its operating range. These shifts often appear as implausible but repeatable data patterns rather than random noise.

This dependency links sensor diagnostics directly to Battery, Power Supply & Ground Diagnostics.

Signal Line Integrity and Noise Influence

Signal lines are susceptible to electromagnetic interference, impedance mismatch, and crosstalk. High-current circuits, electric motors, ignition systems, and high-voltage components introduce noise that may couple into sensor wiring.

Distorted signals affect edge detection, frequency measurement, and analog-to-digital conversion accuracy. For position and speed sensors, timing distortion produces calculation errors that compound across control cycles.

Correlation Between Multiple Sensors

Modern ECUs validate sensor plausibility through correlation. Redundant or related sensors are compared continuously to detect inconsistencies.

For example, airflow estimation combines MAF, MAP, throttle position, and engine speed data. When correlation deviates beyond acceptable limits, ECUs may substitute default values or enter fallback strategies.

Correlation diagnostics determine whether a fault originates from a single sensor or from shared influences such as reference voltage instability or wiring degradation.

Dynamic Signal Behavior Under Operating Conditions

Sensor performance varies with temperature, load, vibration, and operating state. A sensor may behave normally at idle but degrade under acceleration, thermal expansion, or high-speed operation.

Dynamic diagnostics evaluate sensor output during transitions rather than steady-state conditions. These transitions expose latency, hysteresis, and non-linear behavior that static tests cannot reveal.

Frequency-Based and Digital Sensors

Speed and position sensors often transmit frequency-based or digital signals rather than

analog voltages. The ABS Sensor (Wheel Speed Sensor) and Yaw Rate Sensor rely on precise timing rather than amplitude.

Signal integrity in these systems depends on clean edge transitions, stable reference thresholds, and consistent pulse spacing. Distorted waveforms affect calculation accuracy without triggering immediate communication faults.

Sensor Data Validation in Networked Systems

Sensor data travels across vehicle networks before reaching consuming modules. Network latency, message loss, or synchronization errors alter data timing rather than value.

This interaction links sensor diagnostics to CAN Bus, LIN Bus & In-Vehicle Network Diagnostics. A valid sensor signal may become invalid after transmission due to network instability.

Validating sensor data therefore includes confirming both signal generation and data delivery.

Sensor Influence on Control Strategies

Control systems adapt behavior based on sensor trends. Long-term adaptations adjust fuel trims, throttle response, and system thresholds.

Gradual sensor drift influences adaptation logic, masking faults until adaptation limits are reached. When limits are exceeded, sudden fault emergence appears unrelated to recent operating conditions.

Understanding adaptation behavior requires historical sensor data interpretation rather than instantaneous readings.

Sensor Integrity in Advanced Driver Assistance Systems

ADAS functions depend on multi-sensor fusion. Camera, radar, ultrasonic, and inertial sensors combine data to construct environmental models.

Sensor fusion algorithms assume synchronized, validated inputs. A single drifting sensor introduces systemic perception errors without triggering localized faults.

Systems such as ADAS (Advanced Driver Assistance Systems) therefore require sensor integrity validation beyond individual component checks.

Sensor Diagnostics as a Decision Quality Layer

Sensor signal integrity determines the quality of every downstream decision. Actuator control, safety logic, and adaptive learning rely on accurate inputs.

Without validated sensor data, functional diagnostics lose meaning. Sensor diagnostics form a critical layer between network stability and system behavior analysis.

This pillar integrates directly with: