Diagnostics Workflow, Verification & System-Level Validation

- chepqofficial

- Dec 19, 2025

- 3 min read

Updated: Dec 30, 2025

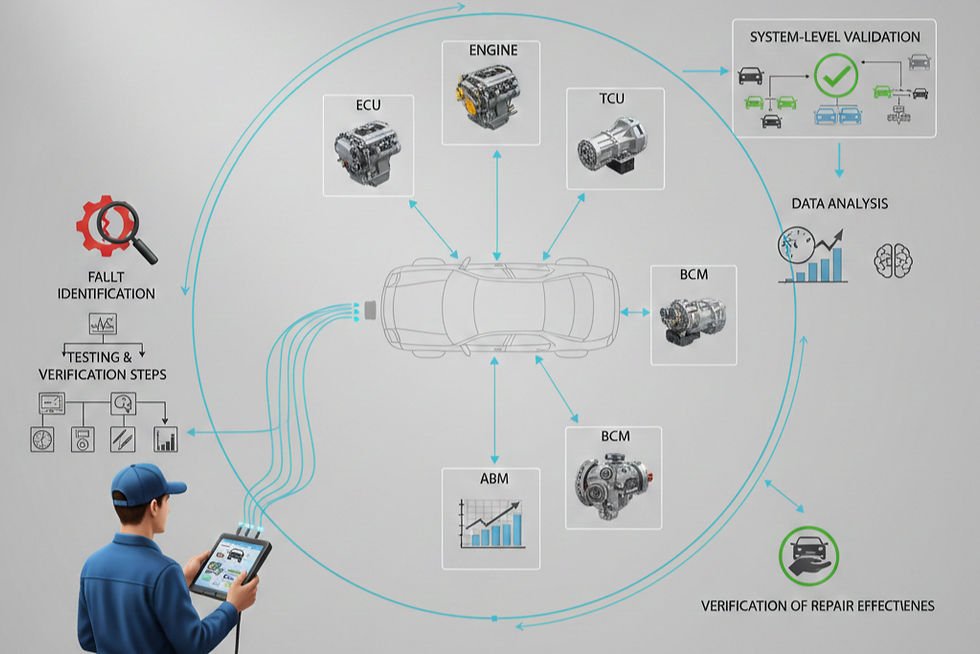

Accurate diagnostics is not a single measurement or test result. It is a structured workflow that moves from symptom observation to system verification, ensuring conclusions reflect actual vehicle behavior.

Diagnostic workflows organize data acquisition, interpretation, confirmation, and validation into a coherent process.

Diagnostic Workflow as a Control Process

Diagnostics follows a controlled sequence. Each step constrains interpretation and prevents premature conclusions.

Workflow discipline reduces noise, confirmation bias, and misattribution. Skipping steps compresses complexity at the cost of accuracy.

Diagnostics workflows formalize reasoning rather than replace expertise.

Symptom Definition and Context Establishment

All diagnostics begins with symptom definition. Observable behavior establishes system context before any tool interaction.

Symptoms define operating conditions, triggering scenarios, and temporal patterns. Without context, data lacks meaning.

Diagnostic workflow anchors measurement to real-world behavior.

Baseline Data Collection

Baseline data establishes reference conditions. This includes system states, environmental variables, and known-good parameters.

Baseline acquisition precedes fault isolation. Deviations gain meaning only relative to reference behavior.

Workflow integrity depends on baseline clarity.

Progressive Isolation Strategy

Diagnostics proceeds from system-level observation to subsystem isolation. Broad evaluation precedes targeted testing.

Isolation narrows fault domains without prematurely excluding interacting systems. Over-isolation obscures root causes.

Structured narrowing preserves causal relationships.

Signal Correlation Across Domains

Modern vehicles exhibit cross-domain interactions. Mechanical, electrical, network, and software layers influence one another.

Workflow validation correlates signals across domains to identify causal alignment rather than coincidence.

Correlation distinguishes symptom from source.

Temporal Validation and Repeatability

Single observations rarely confirm faults. Diagnostics requires repeatability under controlled conditions.

Workflow validation includes time-based verification. Faults must reappear consistently when conditions recur.

Repeatability separates transient noise from systemic issues.

Active Testing and Controlled Intervention

Active tests introduce controlled changes to observe system response. Actuation, adaptation resets, and forced states probe causality.

Workflow structure ensures interventions occur after observation, not before.

Controlled action validates hypotheses.

Data Interpretation and Hypothesis Testing

Interpretation converts measurements into explanations. Hypotheses emerge from observed patterns, not isolated values.

Workflow discipline requires hypotheses to be testable and falsifiable.

Diagnostics is an iterative reasoning process.

Fault Confirmation and Verification

Confirmed faults meet multiple criteria: repeatability, correlation, and response to intervention.

Verification ensures identified faults explain all observed symptoms, not just a subset.

Partial explanations signal incomplete diagnostics.

Post-Repair Validation

Repair actions alter system behavior. Validation confirms resolution under original symptom conditions.

Absence of faults without functional verification remains insufficient.

Workflow closure requires confirmation, not assumption.

System-Level Validation

Vehicles operate as integrated systems. Validation considers interactions beyond the repaired component.

System-level validation ensures no secondary effects emerge after intervention.

Holistic validation protects against cascading issues.

Diagnostic Documentation and Traceability

Diagnostics generates knowledge. Documentation preserves reasoning, observations, and outcomes.

Traceability supports future diagnostics, trend analysis, and accountability.

Workflow maturity includes record integrity.

Workflow Adaptation Across Technologies

EVs, ADAS, and connected systems expand diagnostic complexity. Workflows adapt but do not dissolve.

Structured reasoning scales across technologies.

Workflow consistency enables cross-platform diagnostics.

Human Factors in Diagnostic Workflow

Cognitive load, bias, and assumption influence diagnostics. Workflow structure mitigates human error.

Discipline complements experience rather than constrains it.

Human-centered workflow design enhances accuracy.

Diagnostic Workflow as Quality Control

Workflow validation functions as quality control for diagnostics. It ensures conclusions withstand scrutiny.

Reliable diagnostics emerges from process integrity, not isolated expertise.

Integration Within the Diagnostic Framework

This pillar integrates with:

Workflow coherence connects tools, data, and reasoning.